ULPMAT is a professional manufacturer of coating materials, dedicated to supplying the highest quality sputtering targets and evaporation materials.

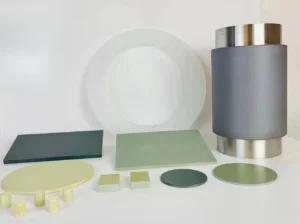

We offer a full range of sputtering targets including metals, alloys, ceramics and custom composite targets. Whether you need flat or rotary targets, we have the expertise to meet a wide range of applications.

What Are Sputtering Targets?

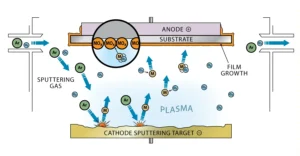

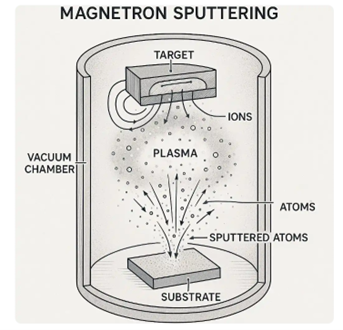

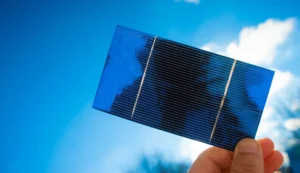

Sputtering targets are the core components in the sputtering process, serving as the materials bombarded by high-speed ion beams to provide the source atoms for thin film deposition. In the physical vapor deposition (PVD) process used in electronic device manufacturing, high-purity sputtering targets play a vital role. They are essential materials for producing electronic thin films on surfaces of wafers, displays, solar cells, and other advanced equipment.

In simple terms, sputtering targets are key materials used in PVD technology. This technology can be seen as a microscopic “metal transfer” process, where high-energy particles strike the target surface, causing atoms to be ejected—or “sputtered”—and deposited onto the substrate to form a thin film. The sputtering target serves as the “raw material” in this precise and controlled material transfer.

Classification of Sputtering Targets

By material type:

By shape/structure:

How Do Sputtering Targets Work?

Performance Requirements for Sputtering Targets

– Purity: ≥ 99.9% to ensure film quality and properties.

– Density: Higher density reduces contamination and enhances uniformity.

– Chemical Uniformity: Stable film composition relies on material homogeneity.

– Crystal Structure: Optimized for efficiency and deposition quality.

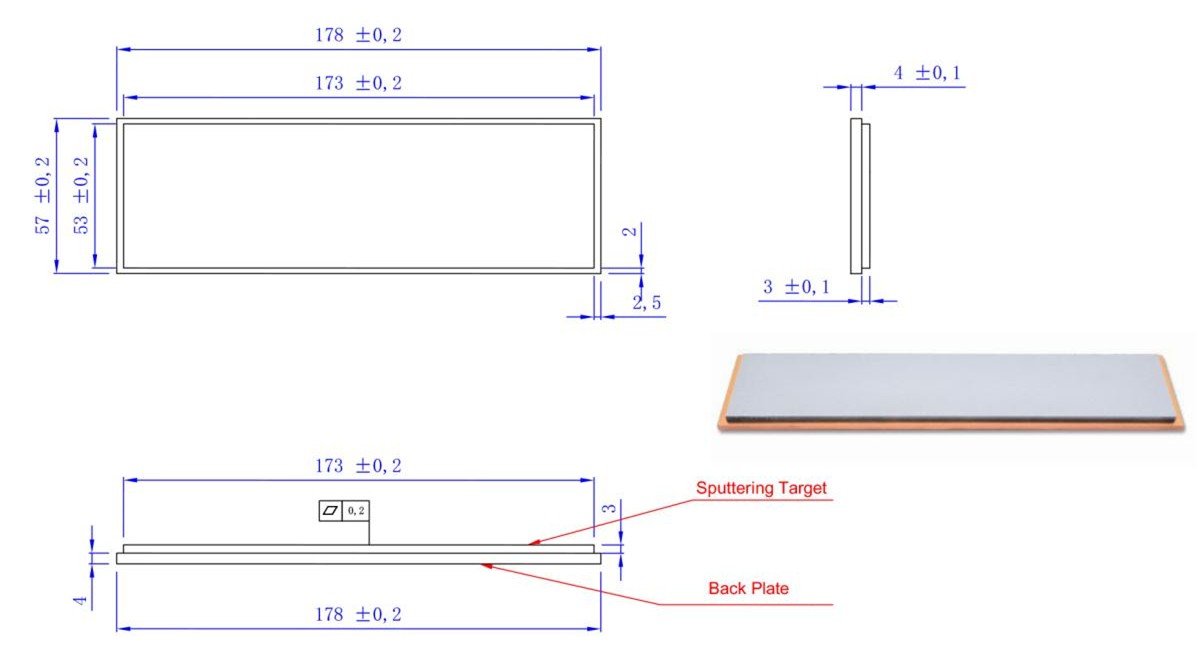

– Shape Accuracy: Must match equipment specs for stable mounting.

– Thermal Stability: Withstands high temp and particle impact.

– Corrosion Resistance: Extends operational life of the target.

Sputtering Target Fabrication Methods

Properties of Sputtering Targets

Purity: Minimizes impurities affecting film quality

Density: Enhances sputtering performance

Conductivity: Maintains process stability

Thermal Stability & Corrosion Resistance: Crucial for harsh conditions

Application Fields

Contact us today to discuss your sputtering target needs — and let us help you achieve exceptional thin film results.