High purity Sputtering targets & Inorganic Chemical Powders

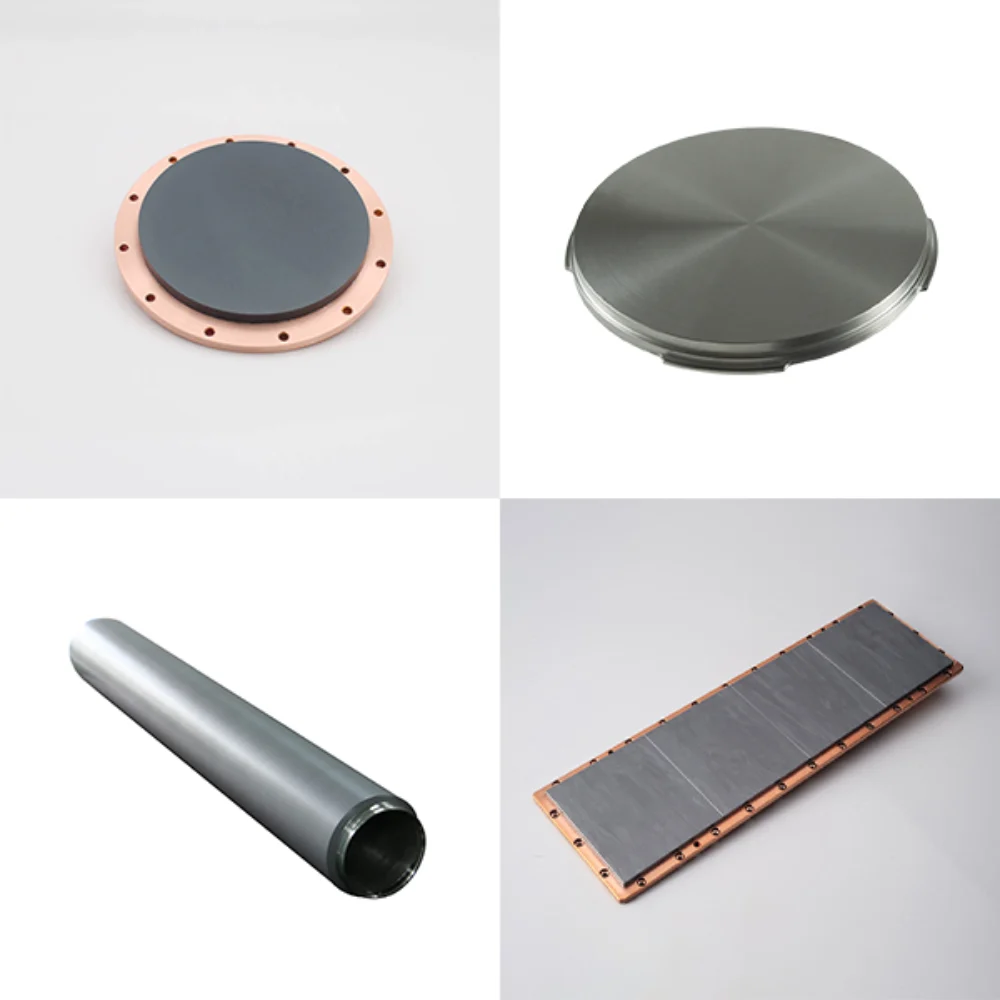

Sputtering Targets

Sputtering targets are essential coating materials in PVD (physical vapor deposition), where high-energy ion bombardment transfers target atoms or molecules onto a substrate to form functional thin films. We offer sputtering targets with high purity, density, and uniformity to ensure excellent coating performance.

Our products include metal, alloy, and ceramic targets, available in various shapes such as circular, rectangular, tubular, triangular, and custom designs. We provide tailored solutions in different sizes and composition ratios to meet your specific application requirements.

Evaporation Materials

Evaporation materials are used to form thin films by heating solids in a vacuum, allowing atoms or molecules to evaporate and condense on a substrate surface. In high vacuum, reduced gas collisions enable free migration of evaporated particles, resulting in uniform film formation.

We offer a wide range of evaporation materials, including pure metals, alloys, and compounds (such as oxides, fluorides, and sulfides), available in pellets, granules, beads, tablets, and custom shapes. Customization of purity, size, and composition is available to suit your specific thin film process requirements.

Ultra-high Purity Materials

Ultra-high purity materials feature extremely low impurity levels, often at the ppb level, offering exceptional physical and chemical stability. Their high purity helps enhance product performance and minimize adverse effects in sensitive applications.

ULPMAT offers ultra-high purity materials such as Si, Te, Cd, In, Ga, Sb, As, Al, Se, Bi, and Sn in various forms, including blocks, granules, rods, and custom shapes. We ensure top performance through strict control of raw materials, preparation, and transport, and support customization of purity, size, and packaging to meet specific customer requirements.

Inorganic Powders

High-purity inorganic powders (3N-5N or higher) ensure low contamination and stable performance in sensitive manufacturing and R&D. ULPMAT offers a wide range with test reports for composition, particle size, and traceability.

Our offerings include battery materials, chalcogenides, halides, rare earth powders, refractory compounds (carbides, nitrides, borides, silicides), nano powders, 3D printing spherical powders, and thermal spray powders. We also provide customized solutions to meet your specific application needs.

ABOUT US

UltraPurMat Group Co., Ltd (ULPMAT) specializes in high-purity film deposition materials and advanced inorganic powders. As an integrated R&D, manufacturing, and sales company, we focus on continuous innovation in the advanced materials field, supported by a professional technical team and a complete production-service system.

Our core business includes deposition coating materials (pure metal, alloy, ceramic sputtering targets, and evaporation materials) and inorganic compound powders (high-purity metals, rare earths, chalcogenides, halides, nitrides, borides, silicides, etc.). Serving industries such as semiconductors, aerospace, electronics, and new energy, ULPMAT collaborates with top universities and institutes, offering joint labs, expert partnerships, and customized solutions to meet evolving customer needs.

Why Choose Us?

Professional Expertise

We are a trusted supplier of high-purity deposition materials and inorganic powders, serving critical industries such as semiconductors, solar energy, optics, battery materials, 3D printing, and thermal spraying.

Outstanding Quality

With strict quality control processes in place, we ensure our materials deliver exceptional purity, consistency, and reliability—fully meeting demanding industrial standards.

Tailored Solutions

We understand that every project is unique. That’s why we offer customized solutions to meet your specific requirements in terms of shape, size, and composition.

Reliable Delivery

Thanks to our efficient and dependable supply chain, we guarantee on-time delivery and maintain stable inventory to keep your operations running smoothly.

Collaborative Innovation

We partner with you to develop innovative material solutions that help you stay competitive in a rapidly evolving technological landscape.

After-sales Support

Our experienced support team is here to provide timely technical assistance and dependable after-sales service—ensuring long-term satisfaction and smooth operation.

News

Lithium-based batteries have become integral to modern technology, powering everything from portable electronics to electric

2025

08 06

Lithium-based batteries have become integral to modern technology, powering everything from portable electronics to electric vehicles. Within the realm of...

2025

04 22

In the realm of modern manufacturing, innovation is the key to staying ahead of the curve. Among the myriad of...