ULPMAT is a professional manufacturer of coating materials, dedicated to supplying the highest quality sputtering targets and evaporation materials.

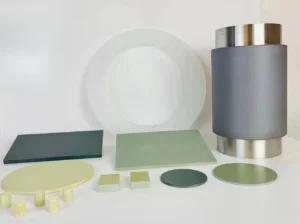

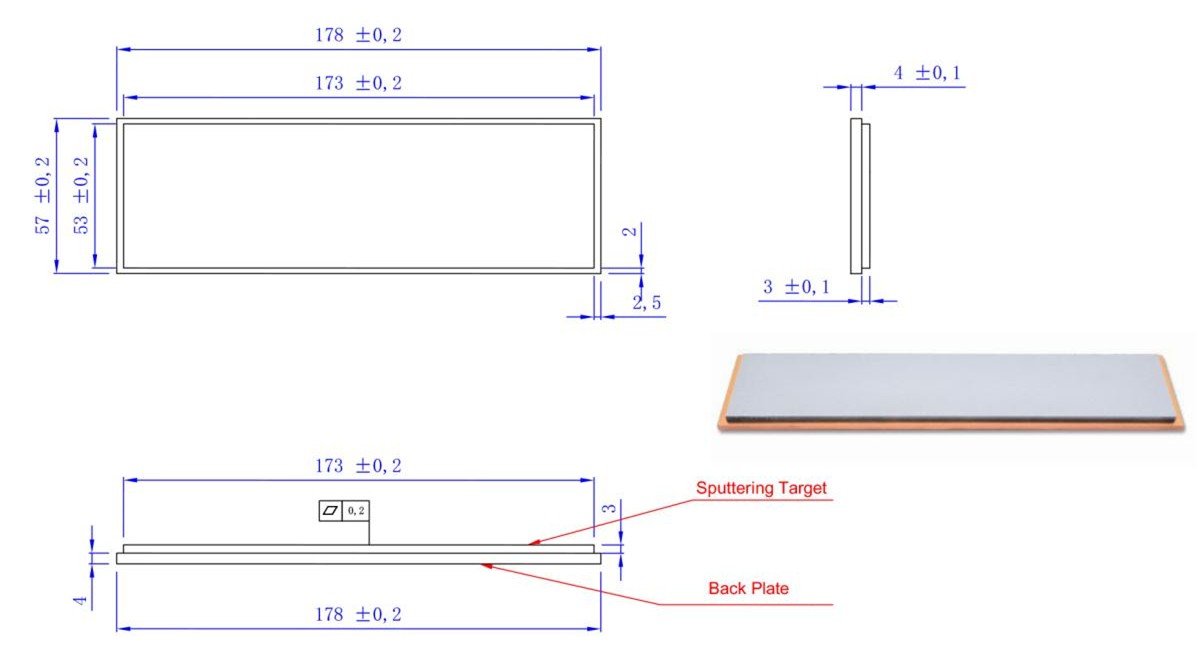

We offer a full range of sputtering targets including metals, alloys, ceramics and custom composite targets. Whether you need flat or rotary targets, we have the expertise to meet a wide range of applications.

What Are Sputtering Targets?

Sputtering targets are key materials in the Physical Vapor Deposition (PVD) process. They serve as the source atoms that are bombarded and transferred onto substrates to form thin films. Applications include semiconductors, displays, solar panels, and precision coatings.

Think of it as a microscopic “metal transfer”—where high-energy ions knock atoms off a solid target and deposit them onto a substrate surface.

Classification by Material

Classification by Shape

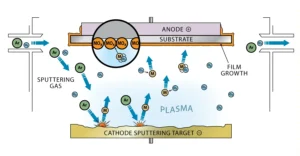

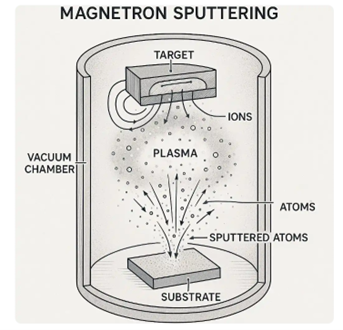

How Sputtering Works

1. Gas Ionization: Argon is ionized in a vacuum.

2. Ion Bombardment: High-energy ions hit the target surface, ejecting atoms.

3. Thin Film Deposition: Ejected atoms condense on the substrate to form a film.

Performance Requirements

Fabrication Processes

Key Properties

Applications

Semiconductors: Metal and dielectric films for ICs and packaging

Displays: LCD, OLED layers including TCOs and emitters

Solar Cells: Si and CIGS films to enhance efficiency

Optics: AR coatings, filters, mirrors

Aerospace: Wear-resistant, protective coatings

Contact us today to explore our full range of high-performance sputtering targets — and let’s work together to achieve exceptional thin film results.