Sputtering Targets Overview

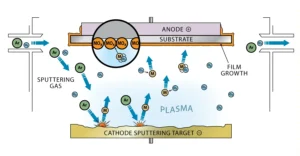

Sputtering targets are core components in the sputtering process, bombarded by high-speed ion beams to provide source atoms for thin film deposition. In Physical Vapor Deposition (PVD) used in electronic manufacturing, high-purity sputtering targets are vital. They enable production of electronic thin films on wafers, displays, solar cells, and other advanced equipment.

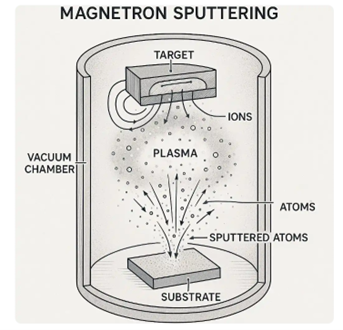

Simply put, sputtering targets are the “raw materials” in a microscopic metal transfer process. High-energy particles strike the target, ejecting (“sputtering”) atoms that deposit on substrates to form thin films.

Classification of Sputtering Targets

By material type:

- Metal Targets: Pure metals like silicon, aluminum, titanium, tungsten, etc.

- Alloy Targets: Metal combinations, e.g., tungsten-molybdenum, titanium-aluminum alloys.

- Ceramic Targets: Non-metallic compounds like aluminum oxide (Al₂O₃), zinc oxide (ZnO), indium tin oxide (ITO).

- Composite Targets: Multi-element materials including nitrides, carbides, sulfides, silicides.

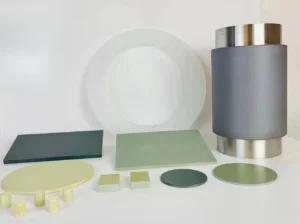

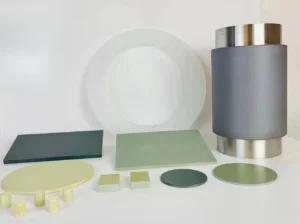

By shape and structure:

- Planar Targets: Circular, rectangular, triangular, ring-shaped, and custom shapes; commonly used in magnetron sputtering.

- Rotary Targets: Cylindrical targets that rotate during sputtering to improve utilization and film uniformity.

How Sputtering Targets Work

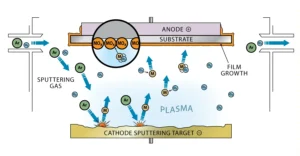

Gas Ionization: Argon gas in vacuum is ionized by high voltage to produce ions.

Ion Bombardment: Ions accelerate and strike the target surface, ejecting atoms from its lattice.

Thin Film Deposition: Ejected atoms travel and deposit onto substrate, forming a thin film.

Performance Requirements for Sputtering Targets

- Purity: ≥99.9% to ensure deposited film quality and performance.

- Density: High density reduces contamination, improves film uniformity.

- Chemical Composition Uniformity: Ensures stable deposited film properties.

- Crystal Structure: Proper structure enhances sputtering efficiency and film quality.

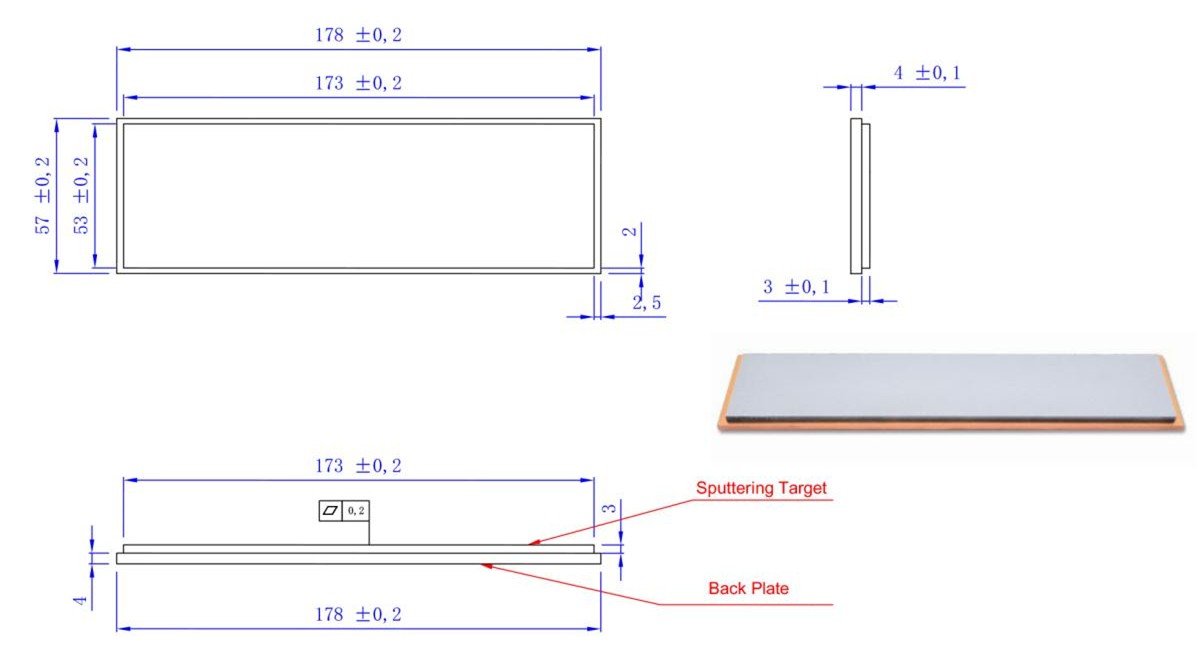

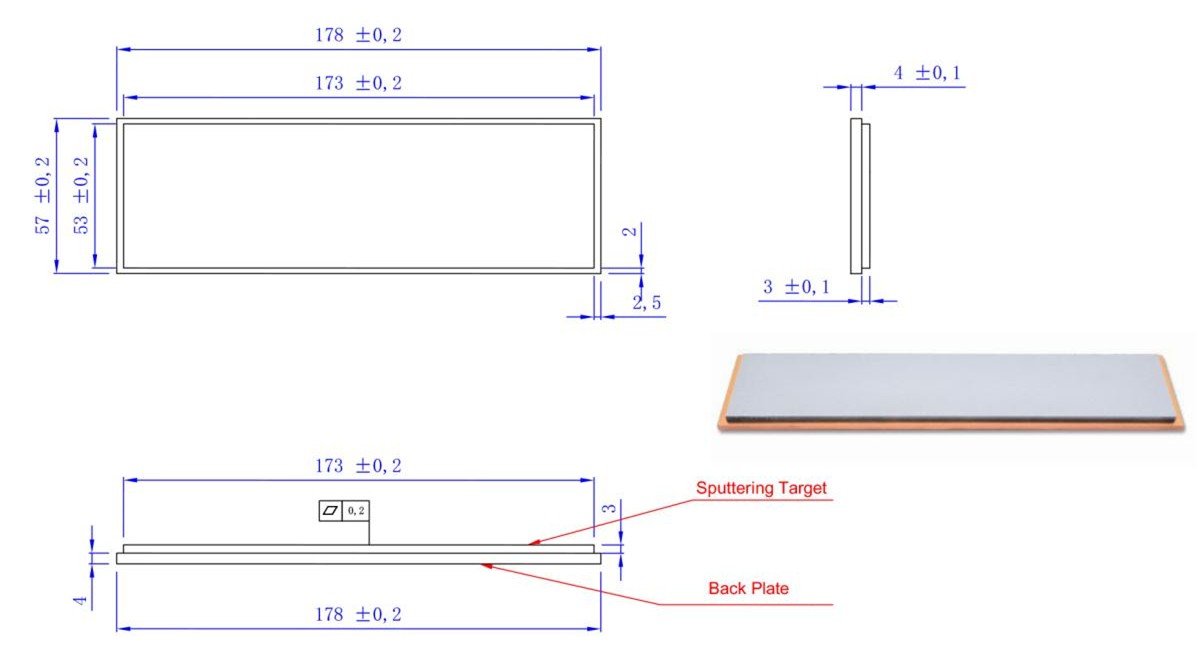

- Size and Shape Accuracy: Must meet equipment requirements for good installation and effect.

- Thermal Stability: Target endures high temperature and energetic particles.

- Corrosion Resistance: Extends service life of the target material.

Sputtering Target Fabrication Processes

- Melting and Casting

Materials: Metals and some alloys.

Process: High-purity metals melted under vacuum or inert atmosphere and cast.

Pros: Low cost, mass production, uniform composition, large targets.

Cons: Not for high melting or oxidation-sensitive metals (e.g. Ti, W, Mo), lower density.

Applications: Aluminum, copper, chromium targets.

- Powder Metallurgy (PM)

Materials: Metals, alloys, ceramics, composites.

Process: Powders mixed, compacted (e.g. CIP), sintered at high temperature.

Pros: Ideal for high melting or complex materials, high purity and density, flexible composition.

Cons: Strict atmosphere and temperature control needed.

Applications: Ceramic (Al₂O₃, ZnO, TiO₂), alloy (Ti-Al, Cr-Ni) targets.

- Hot Isostatic Pressing (HIP)

Materials: Metals, alloys, ceramics.

Process: Powders densified under high temperature and pressure.

Pros: Very dense targets with excellent properties.

Cons: Expensive; not ideal for oxidation-sensitive materials.

Applications: Nitride, oxide, boride ceramics, high-performance composites.

- Spark Plasma Sintering (SPS)

Materials: High-entropy alloys, ceramics, metal compounds.

Process: Fast sintering using pulsed electric current and pressure.

Pros: Short time, minimal grain growth, good composition retention.

Cons: High equipment cost, suited for lab or small batches.

Applications: High-performance or research-grade ceramic and alloy targets.

- Cold Pressing + Hot Sintering

Materials: Metals, ceramics, composites.

Process: Powders cold-pressed, then sintered in vacuum or inert gas.

Pros: Simple, lower cost than SPS, easy size/shape control.

Cons: Density lower than HIP, better for small/medium targets.

Applications: Standard metal, alloy, ceramic targets.

Properties of Sputtering Targets

- Purity: Minimizes impurities that affect thin film properties.

- Density: Enhances sputtering efficiency and reduces porosity.

- Electrical & Thermal Conductivity: Ensures process stability.

- Corrosion Resistance & Thermal Stability: Reliable performance under extreme conditions.

Applications of Sputtering Targets

Semiconductors: Metal and dielectric films to enhance IC performance.

Displays: LCD, PDP, OLED manufacturing for transparent conductive and emissive layers.

Solar Cells: Forming silicon and CIGS thin films to improve efficiency.

Optics: Anti-reflective, reflective, and filter coatings for lenses and instruments.

Aerospace: Protective and wear-resistant coatings for durability in harsh environments.

Contact us today to discuss your sputtering target needs — let us help you achieve exceptional thin film results.