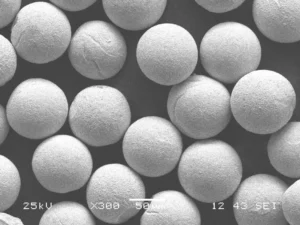

Spherical Powders | High Flowability, High Precision

ULPMAT offers a wide range of aerosolised spherical metal powders. We strictly control composition, sphericity and purity to meet your additive manufacturing needs with reliable quality, consistent supply and customisable solutions. Whether for research or industrial-scale production, our powders provide consistent performance and excellent results.

Spherical Powders for Additive Manufacturing

Spherical powders are finely controlled metal or alloy particles with a near-perfect spherical morphology, produced specifically for additive manufacturing technologies such as selective laser melting (SLM), electron beam melting (EBM) and binder jetting. Their uniform shape and narrow particle size distribution result in excellent powder flow, high packing density and excellent layer consistency during printing.

Spherical Powder Properties:

Commonly Used Spherical Powder Materials:

Key Parameters for Spherical Powders:

Applications: