Solar Photovoltaic

Powering the Future with Advanced Solar Solutions

Solar Photovoltaic Materials Overview

Photovoltaic materials are the core of solar cells, enabling the direct conversion of sunlight into electricity via the photovoltaic effect. As global demand for clean energy increases, advanced PV materials play a critical role in improving conversion efficiency, durability, and scalability.

How Photovoltaic Materials Work

When sunlight hits a solar cell, photons excite electrons in P-type and N-type silicon, forming electron-hole pairs. These charge carriers are then collected to produce electricity. The efficiency of this process depends heavily on the materials used.

Types of Photovoltaic Materials

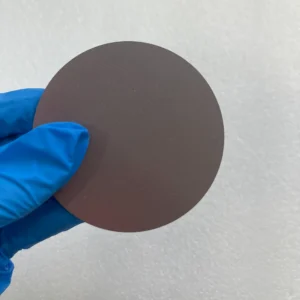

Silicon-Based Photovoltaic Materials

- Monocrystalline Silicon (Mono-Si)

- Polycrystalline Silicon (Poly-Si)

- Amorphous Silicon (a-Si)

Compound Thin-Film Photovoltaic Materials

- Copper Indium Gallium Selenide (CIGS)

- Cadmium Telluride (CdTe)

Perovskite Photovoltaic Materials

- Cesium Lead Iodide (CsPbI3) and other inorganic perovskites

Conductive Thin-Film (TCO) Materials

- Indium Tin Oxide (ITO)

- Fluorine-doped Tin Oxide (FTO)

- Aluminum-doped Zinc Oxide (AZO)

Coating & Doping Materials

- Coating: SiO2, Al2O3, TiO2, MgF2

- Doping: Phosphorus (P), Boron (B), Silver (Ag), Lithium (Li), Sodium (Na)

Wide Range of PV Material Options

We offer customized and standard-grade materials including:

- Monocrystalline Silicon (c-Si)

- Polycrystalline Silicon (Poly-Si)

- Amorphous Silicon (a-Si)

- AZO, CdTe, CdSe, CdS, CdZnTe

- CsPbI3, CsPbBr3

- CIGS, CuInSe2, CZTS

- GaAs, InP, In2S3, ITO

- ZnS, CdWO4, Cd2SnO4

Key Properties of Photovoltaic Materials

- Band Gap Energy: Ideal range: 1.1–1.6 eV, enabling high solar conversion efficiency.

- Absorption Coefficient: Higher coefficient allows thinner films and lower cost.

- Carrier Lifetime: Longer lifetime improves charge collection and efficiency.

- Carrier Mobility: High mobility reduces losses and increases output power.

- Defect Tolerance: More tolerant materials are easier to mass-produce.

- Chemical & Thermal Stability: Ensures long-term performance and reliability.

- Processability: Suitable for sputtering, evaporation, printing, etc.

- Environmental Friendliness: Preference for non-toxic and recyclable materials.

Empowering Your Solar Innovation

From wafer-scale silicon and CIGS targets to nanomaterials and encapsulants, ULPMAT is your trusted partner in advancing next-generation solar solutions.

Contact us today to explore our complete PV materials portfolio and unlock the full potential of clean energy.

Contact us

More Information

- PHONE:+86-29-88993870

- WHATSAPP:+8618291498609

- E-MAIL:sales@funcmater.com

- ADDRESS:A11, 5th Floor, Building 5, Digital China Xi’an Science Park, No. 20 Zhangba 4th Road, High-tech Zone, Xi’an, Shaanxi, China.