3D Printing

Precision Additive Manufacturing

3D Printing

High-Performance Spherical Powders for Additive Manufacturing

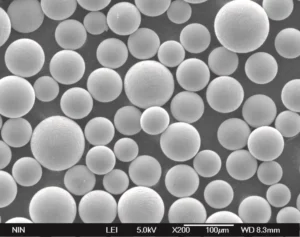

3D printing spherical powder, also known as Spherical Powders for Additive Manufacturing (SPM), refers to high-flowability, high-purity metal or alloy powders with excellent densification properties.

Thanks to their spherical shape, these powders spread evenly, melt consistently, and form high-quality parts during printing. They are essential materials for realizing precision and high-performance 3D-printed components.

Commonly Used 3D Printing Spherical Powder Materials

1. Pure Metal Powders: Titanium (Ti), Aluminum (Al), Copper (Cu), Tungsten (W), Nickel (Ni)

→ Ideal for applications requiring high purity or custom alloying.

2. High-Temperature Alloys: Inconel 718, Inconel 625, CoCrMo

→ Used in aerospace, energy, and high-heat environments.

3. Titanium & Titanium Alloys: Ti6Al4V (Grade 5), Ti64ELI (Grade 23)

4. Aluminum Alloys: AlSi10Mg, AlSi9Cu3

→ Lightweight and high-strength, suitable for structural and aerospace parts.

5. Copper & Copper Alloys: Pure Copper, CuCrZr

→ Excellent thermal and electrical conductivity, used for heat sinks and electrodes.

6. Specialty Metals & Custom Alloys: Tungsten, Molybdenum, Tantalum, Niobium

→ For extreme environments involving high temperature, density, and corrosion resistance.

Key Performance Requirements

- ✔️ High sphericity for smooth flow and powder layering

- ✔️ Narrow particle size distribution for laser/e-beam compatibility

- ✔️ High purity and low oxygen content to reduce defects

- ✔️ High bulk and tap density to ensure dense part formation

- ✔️ Excellent flowability for stable, high-speed printing

- ✔️ No hollow/satellite particles for consistent quality and usage efficiency

Application Areas

- Aerospace: Structural components, turbine blades, and brackets requiring light weight and high strength.

- Medical Devices: Orthopedic implants and dental parts made from titanium alloys or stainless steel powders for biocompatibility and custom fit.

- Automotive: Lightweight structural parts, heat exchangers, and complex tooling to boost efficiency.

- Energy & Industrial Equipment: High-temperature alloy parts used in nuclear, oil & gas, and energy generation sectors.

- Electronics & Thermal Systems: Copper powder used for 3D-printed heat sinks and thermal conductive components.

Why Spherical Powder Matters for Additive Manufacturing

As additive manufacturing transitions from prototyping to mass production, the quality of 3D printing spherical powder directly impacts part precision, strength, and repeatability. Stability, uniform composition, and clean microstructure are key to achieving consistent high-performance results.

Choose ULPMAT, Choose Reliability

- ✅ High Purity & Sphericity: Custom-grade production for demanding applications

- ✅ Custom Particle Size: Compatible with SLM, DED, EBM, and binder jetting systems

- ✅ Consistent Batch Supply: Reliable logistics and strict QC for every lot

- ✅ Application Support: Expert technical support for parameter optimization

📩 Contact us to request samples or discuss your printing requirements. Let us help you unlock the next level of additive manufacturing.

Contact us

More Information

- PHONE:+86-29-88993870

- WHATSAPP:+8618291498609

- E-MAIL:sales@funcmater.com

- ADDRESS:A11, 5th Floor, Building 5, Digital China Xi’an Science Park, No. 20 Zhangba 4th Road, High-tech Zone, Xi’an, Shaanxi, China.